EDIT 6-6-2012: The conclusions in the bottom of this post are incorrect. If you want to read this post and see what my final conclusion is then go to post #148 in the link below. I recommend you read the entire thread if you can because there is a lot of good information to be had that may solve other problems (or make you think you have one  ). http://www.polarisatvforums.com/forums/199476-post148.html

). http://www.polarisatvforums.com/forums/199476-post148.html

In the interest of getting all the symptoms and attempted fixes into one thread I thought I'd share about how I spent the whole summer chasing down and fixing a spitting, sputtering, quitting-while-hot issue on my '06 700 EFI. I know this is very long but I think it will be helpful to those of you that have the same symptoms.

Symptoms:

Rough idling

backfiring

hard starting when cold

cutting out when throttling up

dying after a hard run

POOR gas mileage

It started this Spring with the symptoms above. Other than rough idling and the idle RPMs seemed low; the machine would go for hours and then all of sudden it would start doing the funky chicken like it was starved for fuel. I would wait about 15-20 minutes, start it right up, and all would be well again for the next day or two.

Later I did some reading on this and other forums and found several possibilities that could cause the same symptoms: Temperature-Barometric Pressure sensor wiring broken, the sensor itself is bad, the Throttle Position Sensor is bad, its wiring broken, the fuel pump going bad, and hot gas in the tank.

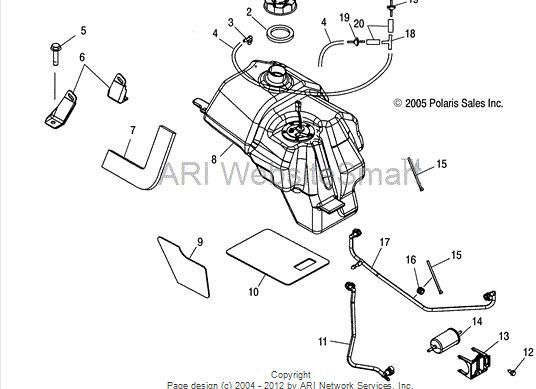

I started with the simple things. I removed and cleaned the T-BAP sensor, fuel tank, fuel lines, fuel rail, and the throttle body. l also replaced the fuel filter and burned a whole tank of fuel treated with Sea Foam. Finally, when I put it back together I double checked all of the connections/clamps from the air box to the intake manifold. None of that fixed the problems.

I decided it was probably the fuel pump. I got the part number from a forum for JUST the pump without the whole friggin' tank assembly, installed it, and called it good...so I thought.

The next trip it worked fine the first day and then BAM! it happened again. Only this time there was no starting it back up so I had to suffer the shame of letting a Honda pull me 8 miles back to camp. I came back to the forums and this time I settled on the T-BAP sensor wiring harness after finding one of the wires to be broken on the inside of the insulation. I ordered a replacement from Only The Best Powersports, installed it, and you guessed it--more ridicule from my Honda friend and back to the forums.

Knowing the wiring was good I went ahead and replaced the T-BAP senor itself. Went riding again, died again, Honda towed me back again. In an unrelated issue, the Gear Position Indicator Switch went south and I had to replace that as well.

Now I turned my attention to the TPS. From the forums, I was able to learn how to check and adjust it--without the special tool and harness from Polaris. The idle voltage was a little low. I adjusted it and started the machine only to hear it keep idling like poo. I had no idea what to do until I pushed on the rubber boot between the air box and the throttle body. When I pushed on it a certain way it purred like a kitten.

I began poking around and as it turns out, there was also a wire broken in the pigtail right where it came out of the TPS. Just like the T-BAP, the insulation was still good but the strands were broken inside (I dissected it later and found it). There wasn't enough wire to work with to splice it back together so I had to replace the sensor.

Fixed, right? Wrong. It died on me the next ride but I was able to restart it after it cooled off again and get back to camp.

During my forum reading, I kept coming across threads that talked about the gas in the fuel tank getting too hot from the exhaust manifold/header and causing the fuel to boil. I dismissed this notion as I thought there was no way gas could boil in the tank without exploding.

Completely baffled, I reluctantly bought a 12" x 12" sheet of insulating foil from NAPA and covered the bottom of the gas tank

I've ridden it hard, really hard, 3 times for several hours each trip now and it runs perfectly. I don't admit it very often but I was wrong. Gas can get too hot and overheat your fuel pump, causing a significant drop in output.

All the other sensor and wiring issues were there too, but I believe it was just coincidence that they all happened at or near the same time. They would definitely cause poor gas mileage and rough idling; however; I think the primary problem causing it to die on me after some hard riding was hot gas in my fuel tank.

Here's what I think fixed the individual issues:

Fuel pump - Nothing. The old one was probably fine.

T-BAP sensor - fixed nothing. These things rarely go bad--no moving parts.

T-BAP Wiring harness - with the correct signal getting to the ECU, this fixed backfiring poor gas mileage, hard cold start and rough idle.

TPS sensor - mechanically, the sensor was probably good but I had to replace it because of where the wire was broken. Fixed backfiring, rough idling, hard starting when cold, cutting out when throttling up, POOR gas mileage.

Foil - prevented gas tank from warming up and overheating the fuel pump. Hasn't died since.

Stew

In the interest of getting all the symptoms and attempted fixes into one thread I thought I'd share about how I spent the whole summer chasing down and fixing a spitting, sputtering, quitting-while-hot issue on my '06 700 EFI. I know this is very long but I think it will be helpful to those of you that have the same symptoms.

Symptoms:

Rough idling

backfiring

hard starting when cold

cutting out when throttling up

dying after a hard run

POOR gas mileage

It started this Spring with the symptoms above. Other than rough idling and the idle RPMs seemed low; the machine would go for hours and then all of sudden it would start doing the funky chicken like it was starved for fuel. I would wait about 15-20 minutes, start it right up, and all would be well again for the next day or two.

Later I did some reading on this and other forums and found several possibilities that could cause the same symptoms: Temperature-Barometric Pressure sensor wiring broken, the sensor itself is bad, the Throttle Position Sensor is bad, its wiring broken, the fuel pump going bad, and hot gas in the tank.

I started with the simple things. I removed and cleaned the T-BAP sensor, fuel tank, fuel lines, fuel rail, and the throttle body. l also replaced the fuel filter and burned a whole tank of fuel treated with Sea Foam. Finally, when I put it back together I double checked all of the connections/clamps from the air box to the intake manifold. None of that fixed the problems.

I decided it was probably the fuel pump. I got the part number from a forum for JUST the pump without the whole friggin' tank assembly, installed it, and called it good...so I thought.

The next trip it worked fine the first day and then BAM! it happened again. Only this time there was no starting it back up so I had to suffer the shame of letting a Honda pull me 8 miles back to camp. I came back to the forums and this time I settled on the T-BAP sensor wiring harness after finding one of the wires to be broken on the inside of the insulation. I ordered a replacement from Only The Best Powersports, installed it, and you guessed it--more ridicule from my Honda friend and back to the forums.

Knowing the wiring was good I went ahead and replaced the T-BAP senor itself. Went riding again, died again, Honda towed me back again. In an unrelated issue, the Gear Position Indicator Switch went south and I had to replace that as well.

Now I turned my attention to the TPS. From the forums, I was able to learn how to check and adjust it--without the special tool and harness from Polaris. The idle voltage was a little low. I adjusted it and started the machine only to hear it keep idling like poo. I had no idea what to do until I pushed on the rubber boot between the air box and the throttle body. When I pushed on it a certain way it purred like a kitten.

I began poking around and as it turns out, there was also a wire broken in the pigtail right where it came out of the TPS. Just like the T-BAP, the insulation was still good but the strands were broken inside (I dissected it later and found it). There wasn't enough wire to work with to splice it back together so I had to replace the sensor.

Fixed, right? Wrong. It died on me the next ride but I was able to restart it after it cooled off again and get back to camp.

During my forum reading, I kept coming across threads that talked about the gas in the fuel tank getting too hot from the exhaust manifold/header and causing the fuel to boil. I dismissed this notion as I thought there was no way gas could boil in the tank without exploding.

Completely baffled, I reluctantly bought a 12" x 12" sheet of insulating foil from NAPA and covered the bottom of the gas tank

I've ridden it hard, really hard, 3 times for several hours each trip now and it runs perfectly. I don't admit it very often but I was wrong. Gas can get too hot and overheat your fuel pump, causing a significant drop in output.

All the other sensor and wiring issues were there too, but I believe it was just coincidence that they all happened at or near the same time. They would definitely cause poor gas mileage and rough idling; however; I think the primary problem causing it to die on me after some hard riding was hot gas in my fuel tank.

Here's what I think fixed the individual issues:

Fuel pump - Nothing. The old one was probably fine.

T-BAP sensor - fixed nothing. These things rarely go bad--no moving parts.

T-BAP Wiring harness - with the correct signal getting to the ECU, this fixed backfiring poor gas mileage, hard cold start and rough idle.

TPS sensor - mechanically, the sensor was probably good but I had to replace it because of where the wire was broken. Fixed backfiring, rough idling, hard starting when cold, cutting out when throttling up, POOR gas mileage.

Foil - prevented gas tank from warming up and overheating the fuel pump. Hasn't died since.

Stew